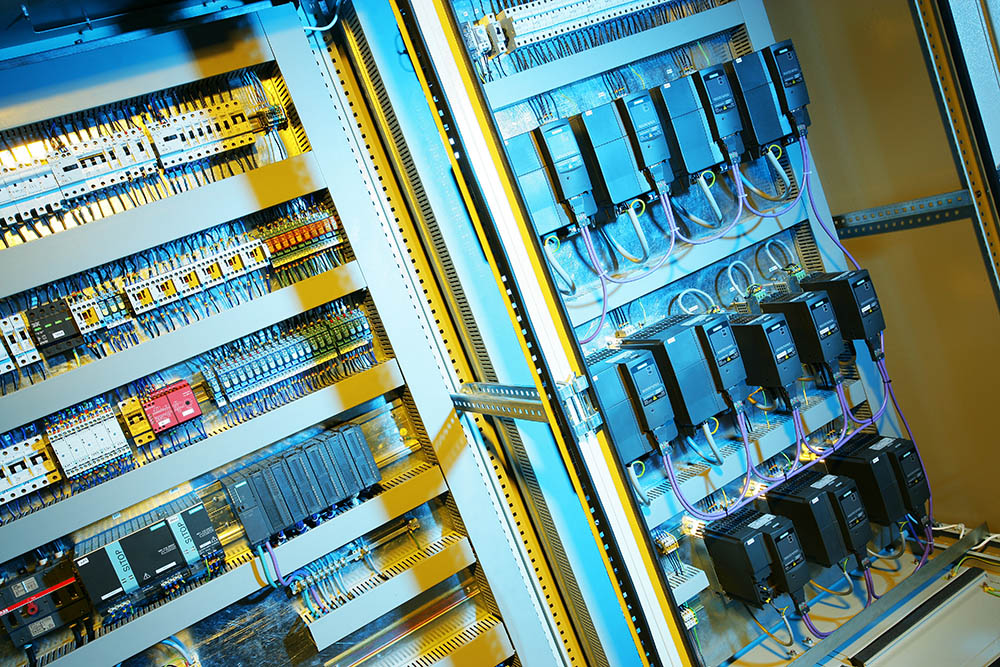

...we have been successfully implementing the automation

of technological processes, robotization and digitalization in industry for 23 years

PROJECTS

7.1.2025Re-engineerig and modernization of the service platform

5.10.2024Palletizing using KUKA robots and final processing of aluminum profiles.

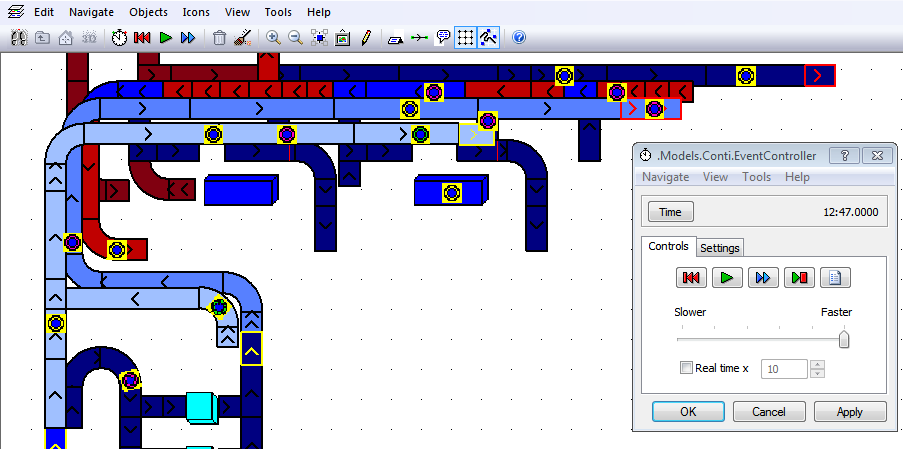

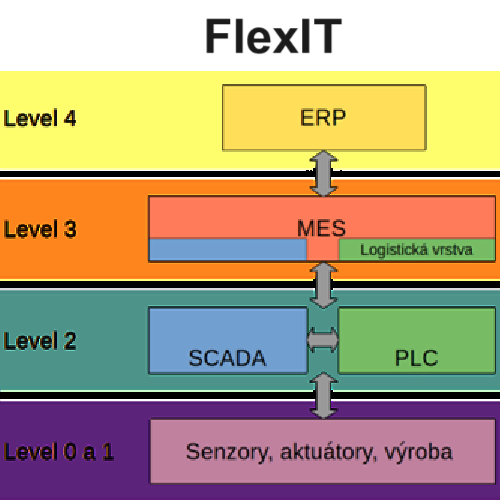

5.10.2024FlexIT – Your Flexible MES Platform

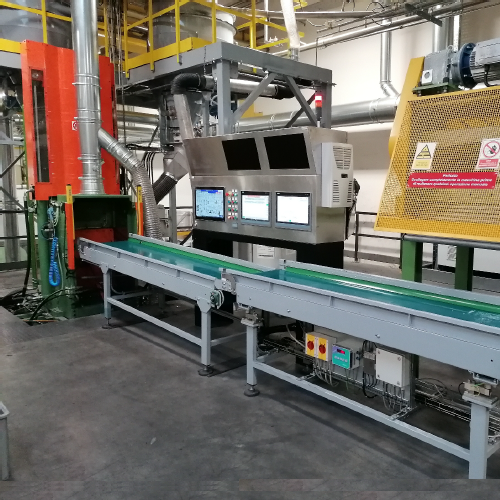

20.6.2024Painting line for acoustic ceiling and wall panels

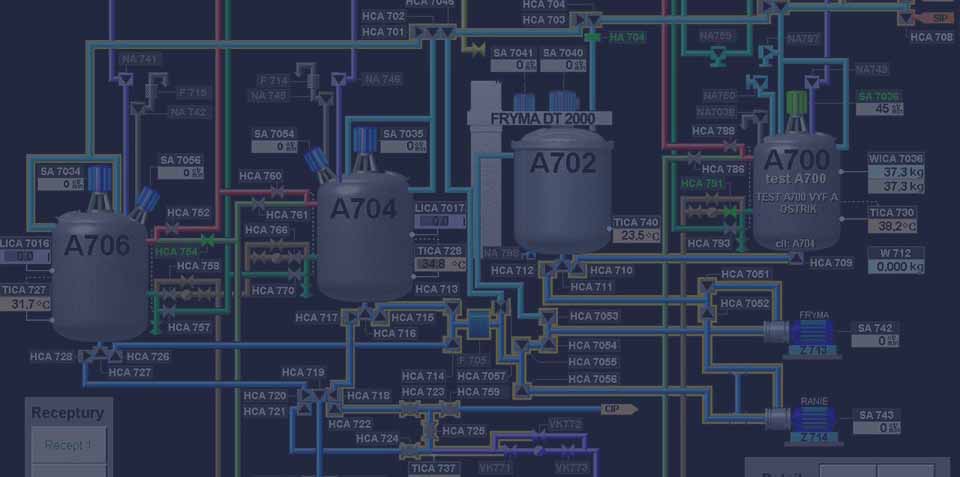

19.6.2024Rubber Mixture Mixer at Hexpol

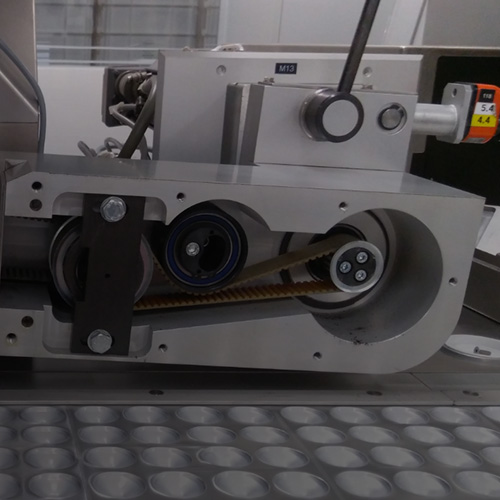

30.11.2020Redevelopment of Blister Machine in Teva