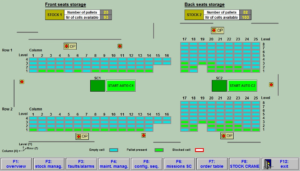

Computerised buffer for front and rear car seats in US

Project – Application Software – Delivery – Commissioning

A computerised 4-floor buffer with 120 cells for front car seats and 9-floor buffer with 158 cells for rear car seats was recently put into a trial operation for the final customer in St. Louis, USA. Two 3-axis manipulators have an autonomous control system Simatic IM151-8 PN/DP and controlled drives supplied from frequency convertors Sinamics S120. A WiFi SCALANCE W748-1 res. industrial communication PROFINET is designed for the communication with the central system Simatic S7-319 PN/DP. Hand-held 2D code readers are networked by PROFIBUS; DI/DO modules and RFID identification systems for pallets are networked by AS-Interface. In sum there are 80 conveyors controlled via 40 Itoh Denki IB-E01 2-zone 24VDC controllers with EthernetIP interface. The buffer’s working cycle is approx. 60 sec.

A hardware platform Simatic PC677 was designed for the SCADA system Simatic WinCC. Local Proface touch panels are available for operators. There is an on-line communication between the buffer PLC control system and the MES/ERP system, that controls all buffer administration.