News

INTRODUCTORY

In this section, we provide you with the latest updates on what we’re currently focusing on. You can look forward to news about our new projects and upcoming presentations, trends and developments in the field of industrial automation, as well as sharing our recent achievements. Don’t forget to check out our webinars, which we host regularly.

NEWS

Take Control of Your Energy Consumption!

Discover where you can reduce costs and increase efficiency with smart energy consumption monitoring. We have prepared a comprehensive solution to help you keep your energy usage under control. Our TAURID solution utilizes IoT sensors and the intelligent platform Siemens Simatic ET200SP and Energy Suit for data collection, analysis, and visualization. It offers integration with machine operating modes or entire production lines, enabling efficient energy management and consumption optimization. You will gain real-time energy consumption monitoring, bottleneck identification, and opportunities for process optimization.

TAURID is a partner of the professional seminar Machine Safety 2025, held on March 19th as part of the AMPER 2025 trade fair in Brno. The seminar will first focus on the new legislation, followed by machine safety in terms of cybersecurity, and lastly, the new ISO 13855 standard for approach speed assessment. You can participate in the seminar FREE of charge in person from 9:00 AM to 12:00 PM, or FOR A FEE by watching the online stream with the option to replay the recording within the next 14 days.

Detailed information can be found on the Elektroprůmysl portal.

We have received an order for the supply of an MES for our long-standing customer in the automotive industry. Our solution has been operating reliably in a production plant in France for more than 10 years, and we are firmly convinced that the planned, upgraded version for the production plant in South Africa will be just as successful.

TRENDS & INNOVATION

Immerse Yourself in the World of Innovation and Digital Transformation

Discover how the latest technologies and modern approaches in automation and digitalization can take your business to the next level.

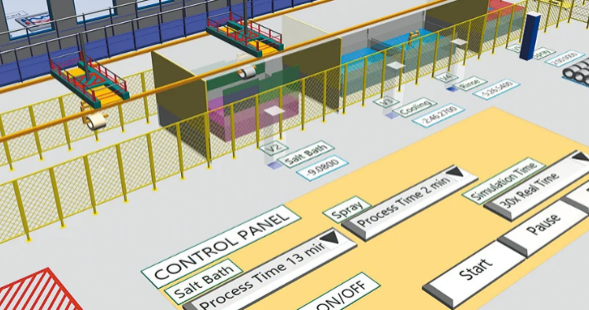

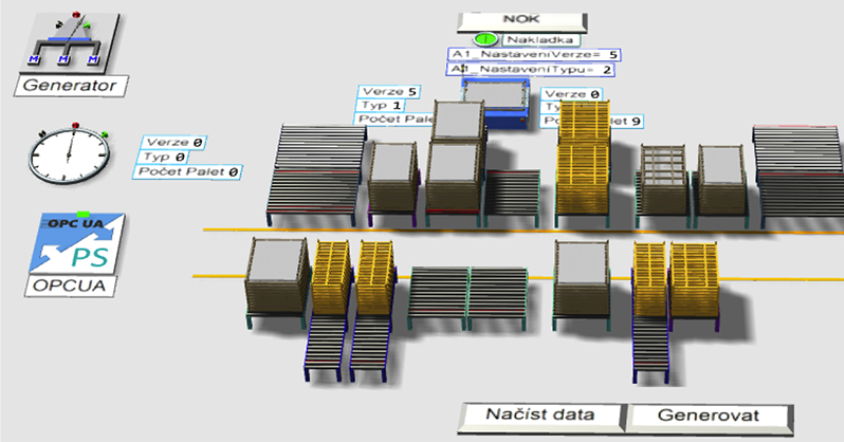

Virtual commissioning in the laboratory reduces the testing time of real systems, allows testing of production batches in an accelerated mode, tests combinations that rarely occur and are difficult to prepare in reality, and last but not least, reduces the psychological burden on employees responsible for commissioning equipment. Read more in the article “Virtual Commissioning is Now a Necessary Condition for the Smooth Start-up of Complex Workplaces”, published in the journal Strojírenství:

Read our post on the topic of “Modern Digital Models and Their Use Not Only for Automation and Robotics of Industrial Production”, which was published in the journal Elektroprůmysl and on the web portal:

WEBINARS

For those interested, we will organize a seminar-webinar where our specialists will present the experiences they have gained while working with 3D digital twins.

We will show you how to create a digital model, how to connect it with the TIA Portal (Siemens) or Studio 5000 (Allen Bradley) development environments, and how the actual testing or virtual commissioning process works. Finally, we will demonstrate the benefits of applying a digital twin, what advantages it provides, and what costs to expect.

Seminar A – Designing a New or Modifying an Existing Production System

Typical customer requests and questions are:

- Safely verify the possibility of increasing production by 20% on the existing production system. What size of an intermediate buffer is necessary?

- Design the layout of a new production system and verify the planned production capacity. What advantage do we gain by preparing virtual commissioning using a digital twin?

- Why is it beneficial for us to have a dynamic production planning system?

- Do we need to identify semi-finished products, or is goal tracking sufficient?

Seminar B – Using Digital Twins for Virtual Commissioning

Typical projects and questions for virtual commissioning are::

- Event-based production systems with a complex logistics control layer

- Branched conveyor systems with buffers, warehouses, in-process buffers, robots, or AGVs

- Assembly lines and workplaces in the automotive industry

- Galvanizing and dip pickling lines

- Are the criteria for event allocation among manipulators on a shared track optimally designed?

Seminar C – Siemens RFID Technology for Industrial Identification

Typical projects and uses of Siemens RFID technology are::

- Authentication of operating personnel using RF1040 in conjunction with Simatic HMI

- Identification of handling hooks using RF260R, IO-Link interface, and MDS124 transponders

The webinar will take place if at least 3 participants express interest. Please provide your preferred date. Choose the topic, preferred date, and register for the webinar via email at robert.hofman@taurid.cz or by phone at 736 602 722 or 599 507 800. Login instructions will be sent to the email address provided. We look forward to seeing you.

After the webinar, we will send you the presentation in PDF format.