Services

- Portfolio

- Specialisation

- SAFE AUTOMATION

- DIGITALIZATION & SIMULATION

- SOLUTION & PARTNERSHIP

- ROBOTS

- WMS/MES

Portfolio

Designing electrical equipment

- designing control system

Siemens, Allen-Bradley (Rockwell Automation), Mitsubishi, CAE EPLAN Electric P8 development environment, low-voltage equipment up to 1000V, designing equipment for the Ex environment, designing equipment falling under the control of CMA, functional specifications, block diagram, P/I diagram, circuit diagrams, material specifications, list of cables, technical report, operating and maintenance manual, list of recommended spare parts

- designing LAN, WLAN industrial networks

Industrial Ethernet (IEEE 802.3), Industrial Wireless LAN (IEEE 802.11a/b/g/h), metallic, optical or wireless, tree topology, line, star or circle, SCALANCE industrial switches, Stratix, networks PROFIBUS, PROFINET, PROFIsafe, RS485, EtherNet/IP, ControlNet, DeviceNet,

- designing electrical controlled drives

decentralized, universal, for pumps/fans, for actuators and precision control, IP2x or Ip5x, Siemens frequency convertors Sinamics V, G, S series, Micromaster 420/430/440, Sinamics DCM, Simoreg 6RA70, security features, Allen-Bradley PowerFlex PF70/700, PF 753/755, DC PoweFlex, Telemecanique Altivar 71/61, ABB, Lenze, NORD, SEW, softstarters, thyristor controllers, Eurotherm and AEG for powering heating elements

Developing application software

- for control systems (PLC)

Siemens Simatic LOGO!, S7-1200, S7-1500, ET200SP, S7-300/400, ET200S, security S7-1200F, S7-1500F, S7-300F, PCS7, Allen-Bradley MicroLogix, CompactLogix, ControlLogix, security Guardmaster, SmartGuard 600, Flex I/O, Compact I/O, Point I/O, Mitsubishi, TIA Portal development environment, STEP7

- for operator panels (HMI)

Siemens Simatic HMI KP, KTP, 400/700/900/1200, touch TP700/2200, mobile panels KTP400/700/900 in standard and security (F) design, WinCC (TIA Portal) development environment, WinCC flexible, Allen-Bradley PanelView Plus 6, PV Plus 400/600/700/1000/1250/1500, FactoryTalk View Supervisor Edition development environment, Panel View Plus 7, FactoryTalk View Machine Edition development environment

- for process visualisation (SCADA)

for applications running on PC hardware, Siemens Simatic, WinCC V7 SCADA, Moravske pristroje ControlWeb

- for controlling processes and production lines (MES)

automated production lines, for the engineering and automotive industry

- software modules and methods

diagnostic and calculation modules for the settings of controlled electric drives, shortening the time of commissioning, communication modules, electronic signatures, Tecnomatix Plant Simulation methods

Modeling, simulation and optimisation

- processing digital models

for a production or assembly line, Siemens Tecnomatix Plant Simulation

- designing production systems

verifying the design parameters for a new or existing event-based production system

- planning and scheduling production

using a digital model, scheduling for a production batch or mix of batches, introducing a new product into production, increasing labour productivity

- simulation analysis and optimisation

proposals for layout modifications, arrangement of resources and transport routes, suggestions for increasing the number of resources or their production capacity

- workshops

organizing seminars with examples of digital models for event-based production systems in Ostrava or Brno

Manufacture of electrical switchboards

- electrical industrial switchboards

low-voltage cabinets and wall mounted panels, control desks, enclosures and junction boxes, Rittal, Schrack Techniques, the EN 61439 standard is applied, design verification

Supplies of goods

- Siemens, Allen-Bradley

complete product assortment of PLC, HMI, SCADA, frequency or DC converters, soft starters, RFID components, low-voltage switching equipment, including security systems

- Rittal, Schneider Electric, ABB, Pilz

product assortment of the mentioned manufacturers is designed, alternatively we can only offer the required parts giving you a qualified review

- SICK, Turck, Pepperl & Fuchs, Euchner

product assortment of the mentioned manufacturers is designed, alternatively we can only offer the required parts giving you a qualified review

Modernisation

- modernization of obsolete control systems

Siemens Simatic S5-95/115/135/150, S7-300/400, Allen Bradley SLC500

- complete modernisation of electrical system

including automation with the use of the latest technology, tracking works-in-progress in the manufacturing process and storing production data in logs for the needs of not only customer audits

Designing and programming FANUC robots

- Dimensioning and programming robots

Choice of the right type of robot, possibility of simulating movements and commands offline using ROBOGUIDE 3D simulation, communicating with other devices via LAN PROFIBUS, PROFINET, Ethernet/IP

- Putting robots into service

Fast commissioning, operator training

Installation and assembly

- installation and assembly at the customer’s workshop

electrical cabinets, cable routes and cables, TAURID assembly capacities, a supervisor for external assembly capacities, CR, Europe, outside Europe

Commissioning

- commissioning at the customer’s workshop

installed machines and production lines, individual and comprehensive tests, FAT, SAT, operator and maintenance training, CR, Europe, outside Europe

Service and technical assistance

- warranty service

for equipment commissioned by TAURID, remote diagnostics, VPN, TeamViewer, telephone consultations, preventive checks

- post-warranty service

priority given to equipment commissioned by TAURID according to the concluded service agreements, or the availability of technician(s)

- technical assistance

24/7 for equipment commissioned by TAURID for others, according to an agreement or the availability of technician(s)

Specialisation

Pharmacy

Liquid dosage forms, batch production, raw material records, labeling machines, pure water production, pure steam generators, particle measurement, warehouse management.

Siemens PCS7 control system, process visualization, trending and archiving of measured values and alarms, creation, printing, and archiving of production protocols, cooperation in validations. Development engineers are members of the ISPE organization.

The control systems comply with the current requirements of EU regulations for GMP, the requirements of the American FDA standard, and the requirements stated in GAMP5. They also comply with the requirements of the CFR 21 Part 11 standard, which sets procedures and technical requirements for the use of computer systems based on electronic data storage and using an electronic signature.

Strip Processing

Longitudinal and transverse coil cutting, surface treatment by mechanical, chemical action and coating application, rewinding and unwinding of the strip, tension regulation, strip centering, weighing, and packaging of output coils.

During the commissioning of the equipment, individual measurements of the mechanical properties of the unwinder and winder drive are carried out to optimize the drive settings for very low tensions. The tension control ensures precise winding and tightening of individual turns on the winder drum.

The strip is cut when stopped or using flying shears. A special case is the cutting of trapezoidal sheets by rotating the shears using Siemens Sinamics S120 frequency converters.

Metal Surface Treatment

Pickling, phosphating, nickel plating, galvanizing, neutralization, exhaust, and absorption. Cascade transport for coils and bars, continuous transport for strips.

Fully automatic or semi-automatic transport, selection of the pickling program – recipes, transport optimization for cascade pickling as a discrete production system with events using software tools, see Computer Simulation >>. The output of the computer simulation is hourly production, confirmation of a sufficient number of manipulators and C-hooks, including their utilization.

The metal surface treatment equipment is exposed to aggressive chemicals, so the materials used for the electrical installation (cable routes, ducts, tie wraps, and fasteners) are responsibly dimensioned with this in mind.

Special Purpose and Assembly Machines for the Electrical and Automotive Industry

Assembly and testing stations for headlights, leak testing, riveting machines, welding machines, screwdrivers, curing ovens, and more.

Monitoring of production processes, sequence control (poka-yoke, pick-to-light), data collection at the technological level in control systems and processing of statistics in monitoring systems (PLC, HMI, SCADA), machine efficiency, fault frequency, continuous quality monitoring.

Product traceability and tracking by ID, raw material identification, barcodes or 2D codes, data export to MS Excel, Access, audit trail, and logging of operator interventions, printing of homologation labels, communication with the warehouse database of the superior IS, communication with external devices, own solutions of compact operator terminals based on GNU/Linux OS.

Transport and Processing of Semi-Finished Products

Conveyor systems, lifts, turntables, transfer cars, welding lines, saws, drying chambers and ovens, weighing systems, palletizers, packing lines, 2-axis/3-axis manipulators.

Insulating materials, acoustic ceilings, steel or aluminum wheels, car seats, steel tubes, rubber hoses.

We carry out the analysis of the production system layout design, verify the basic capacity parameters using computer simulation on the processed digital model, and optimize bottlenecks or collision points.

SAFE & SECURE AUTOMATION

When designing electrical equipment, we consider the safety application standard ČSN EN ISO 13849-1, which uses a risk graph to determine the required safety level and works with the term “required performance level PLr”; less so the ČSN EN 62061 standard, where the method used represents a numerical approach and works with the term “required safety integrity level SIL”.

The general principles for design, assessment, and risk reduction are covered by the type A standard, ČSN EN ISO 12100. The risk assessment is performed for all hazards, the standard defines a sequence of steps, starting with the determination of the machine function.

DIGITALIZATION & PC SIMULATION

The portfolio of services includes the creation of a digital model and subsequent computer simulation of the behavior of a discrete manufacturing system. We specialize in branched conveyor systems with buffers, the production of semi-finished products using intermediate warehouses, assembly lines, and workstations in the automotive industry, and last but not least, galvanizing and tank pickling lines. We use the Siemens Tecnomatix Plant Simulation simulation tool.

Computer simulation helps in designing a new production line, modernizing the existing one, introducing a new product into production, or increasing labor productivity. With a high degree of probability, it can be verified that the proposed concept of technical solution can meet the customer’s requirements.

Bottlenecks or collision points and states are identified, selected speeds, production per unit of time, sufficient number of defined resources, or the capacity of inter-operational buffers are verified, and measures are taken – changing the layout, number of resources, modifying transport flows or decision criteria, all without deploying actual resources (machines, operating personnel).

Directly in the model or in an external MS Excel table, it is possible to define a production batch or mix of batches, recipe, define work shifts, number of functional resources, etc. The result is reports and graphs, answers to questions that help responsible personnel in decision-making. Designers, production managers, investment staff, economists, and company management. They do not make decisions based on estimates and feelings but on facts.

If you are interested in this topic, continue to the link below.

SOLUTION & PARTNERSHIP

Our specialists will help you with the comprehensive design of an industrial identification system using RFID technology, dimensioning suitable data carriers, read/write heads, communication interfaces, and of course, the appropriate configuration of the control and monitoring system, whether on a PLC or PC platform. We offer comprehensive automation and industrial identification solutions for your production line.

TAURID is a certified partner of Siemens for the field of industrial identification. SIMATIC Ident systems include RFID (radio frequency identification) technology and CRS (code reading systems), as well as newly introduced RTLS (real-time locating systems). RFID technology is applicable wherever there is a requirement for greater flexibility and quality of production, tracking the movement of individual semi-finished or final products, or transport baskets, pallets, etc.

If you want to learn more about the concepts: data carrier, read/write head, or communication interface, click on the link below.

FANUC and KUKA robots

We offer automation solutions for production lines using FANUC or KUKA industrial robots. We cooperate with proven gripper suppliers and, at the same time, develop our own robust grippers tailored to specific requirements with our partners.

The robots can work independently, but we usually integrate them into a production system, which we control via PLC. Communication between the PLC and the robot controller is handled via the PROFINET (PROFIBUS) bus for Siemens PLC, or via the EtherNet/IP bus for Allen Bradley PLC.

An advanced solution for robot guidance using machine vision with artificial intelligence is almost essential for applications in dirty environments, with contaminated products, and in environments with variable lighting conditions where it is impossible to shield the workspace and use external lighting.

We offer all pick-place applications from depalletization, transferring semi-finished products for processing, to palletizing. Our solution utilizes top-notch sensors and is capable of synchronizing with moving objects in real-time, for example, for hanging parts on overhead conveyors. Assembly, packaging, or inspection are other applications where speed, accuracy, and flexibility are key.

Are you unsure whether a 6-axis, palletizing, SCARA, or collaborative robot, or a combination of them, would be best? Contact our specialists with a request for dimensioning a stationary or mobile robot with a gripper.

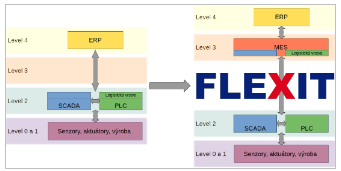

WMS/MES Flexit

Our FlexIT solution is a new management concept that we advocate in the automation, robotics, and digitization of production and process lines in the industry. It provides an effective response to the growing demands related to flexible manufacturing, a wide production portfolio, semi-finished product identification, data archiving, and complex logistical control functions.The still-developing modular system FlexIT belongs to the group of logistics management systems. These are also known by the acronym MES (Manufacturing Execution System), with FlexIT also incorporating elements of WMS (Warehouse Management System). Its application can be imagined, for example, for dip pickling and galvanizing lines, in-process buffers and warehouses, and complex conveyor systems (including AGV/AMR). It separates often complex embedded logistical control functions from the PLC/SCADA layer directly into the MES layer.

The basic modules are:

- Process control

- Communication with superior (ERP) and subordinate (PLC) systems

- Logging and tracking of products and events

- A user-friendly graphical web interface for management